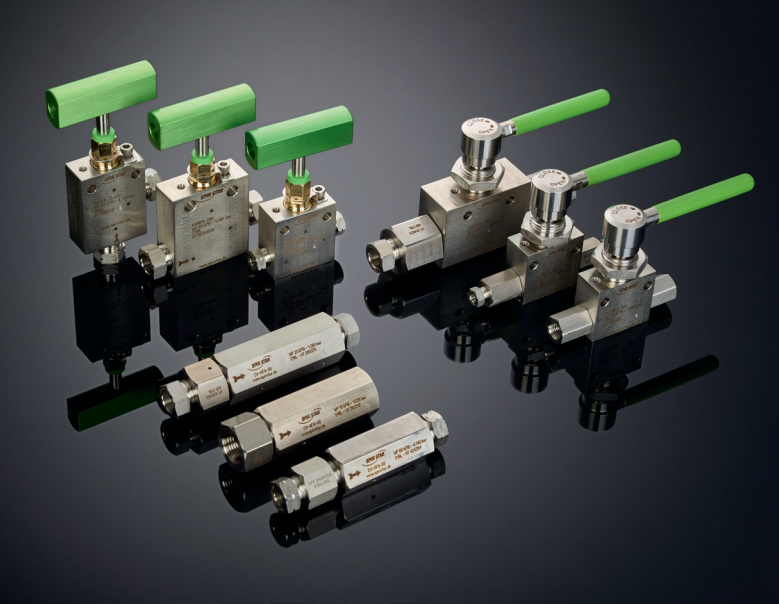

VALVES

Ultra High Pressure Valves: 4160 BAR / 60,000 PSI

SPIR STAR® designs ultra high pressure valves tailored for liquid and gaseous applications, featuring diverse thread types like needle, ball, pressure relief, or check valves. Crafted from cold-forged stainless steel, they endure the extreme temperatures and pressures inherent in such environments, reaching a maximum working pressure of 4160 bar/ 60,000 psi.

Needle Valve

Efficient Operation: SPIR STAR® valves ensure safety and durability, opening or closing in 4 ½ turns for various applications.

Swift Control: Fast-opening valves need only 1 3/4 turns, providing quick responses. All valves allow flow in any direction for flexibility.

Stability in Design: Innovative design reduces vibration, eliminating the need for external clamps. Relief holes enhance overall stability.

Traceability and Convenience: Clear markings ensure traceability, and each valve comes complete with collars and gland nuts.

Versatile Options: SPIR STAR® AG offers pneumatically operated needle valves for diverse operational needs.

Ball Valves

SPIR STAR® prioritizes quality, evident in our high pressure ball valves designed in the durable “trunnion style,” ensuring a longer service life.

These valves, with various orifice options, offer versatility for diverse applications.

Additionally, we provide high pressure ball valves with pneumatic or electric actuation, ensuring flexibility to meet different operational requirements.

Check Valve

Ensure long-lasting performance and prevent backflow and damage in pressure systems with SPIR STAR® high pressure check valves.

Our range includes both ball and O-ring check valves, each tailored for specific applications.

The O-ring check valve is well-suited for gas applications, while the ball check valve excels in high-temperature environments and dynamic applications.

Relief valves, double block and bleed valves

Beyond the high-pressure valves mentioned earlier, SPIR STAR® extends its offerings to include pressure relief valves, crucial for preventing pressure peaks in systems.

For tailored needs, we provide customized solutions such as double block and bleed valves and manifolds upon request.